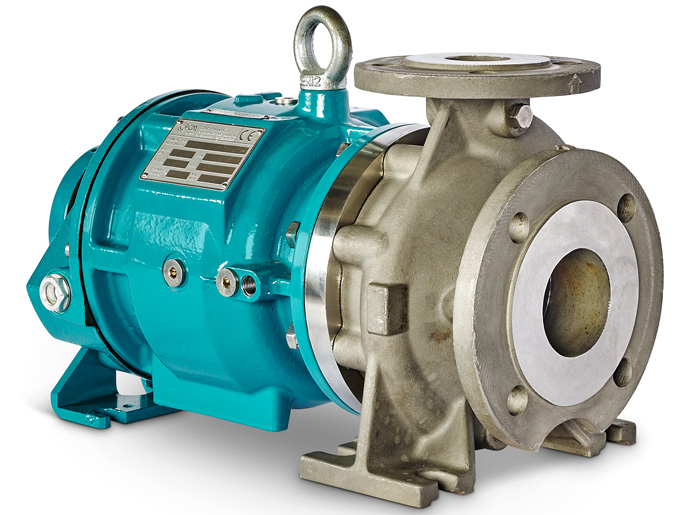

The correct sizing of a centrifugal pump

The main features to consider when choosing the right pump for your application.

When sizing a centrifugal pump it is important to consider it as a part of a hydraulic system, taking care to size it correctly both from a hydraulic and a mechanical point of view. In fact, if you install a pump that is not suitable for the installation, problems can occur which result in maintenance costs, dangerous / expensive liquid leaks, downtime. Sizing a centrifugal pump among the countless options available can be very complicated, therefore it is good to identify first of all:

- the system pressure and the characteristics of the liquid: they are very important in order to guarantee the correct flooding of the pump and its configuration;

- a correct estimate of the budget and of the purchasing costs, considering the actual time of use of the pump: it is necessary to avoid selecting an unsuitable, under or oversized product with the consequent increase in operating costs.

Main features for the correct sizing of a pump

From the hydraulic point of view, identifying the correct centrifugal pump suitable for the system means making sure to consider some important features.The flow rate and the head of a pump

To find out how the flow rate of a centrifugal pump is calculated, it is necessary to know the quantity of liquid that must flow into the pump and at what distance the same liquid must be relaunched within the system. In calculating the head, it is essential to also consider any pressure drops related to the friction of the fluid, the possible presence of valves, reductions, elbow bends on the pipes.What are the characteristics of the pumped liquid to consider for the right choice of a centrifugal pump?

The main characteristics of the pumped fluid to be known for a correct pump selection are:- The nature and the temperature of the medium influence the selection of the pump material. In fact, each material has a different mechanical / chemical compatibility with the pumped fluid and at the same time has a resistance to the operating temperature. Therefore, knowing the type of fluid, its concentration and its temperature allow the correct selection of compatible materials.

- The density and viscosity of the fluid affect the power of the motor to be selected and at the same time the correct sizing of the impeller trim, to ensure the required performance is achieved.

- The presence of solid suspensions in the pumped liquid: this information is important for the choice of the type of centrifugal pump to be selected.

Centrifugal magnetic drive pumps are generally suitable for working with clean or lightly contaminated liquids. CDR Pompe, thanks to its design team, which boasts decades of experience in the magnetic drive field, has managed to overcome this limit by developing the XTN and XTS series, magnetic drive pumps specifically designed to pump liquids with solid suspensions in high concentrations.

What is the maximum efficiency of the pump and its optimal use

From a technical point of view, it is advisable to operate the pump ideally in the point of maximum efficiency (BEP, or Best Efficiency Point), that is between 50 and 110% of the point of maximum performance of the pump, and in any case never at the end of the performance curve. This working point in fact allows to limit to the minimum vibrations, low lubrication and cavitation, and therefore breakages of the pump itself. CDR is able to offer solutions to safeguard the operation of the pump even in working conditions far from the BEP, for example by configuring the pump through the installation of bushes that have a special self-lubricating surface treatment (RunSafe SIC) and able to counteract the lack of lubrication.Another important feature: the cost of maintenance

A significant role in choosing the ideal pump is also covered by the maintenance cost of the same over the medium to long term, not only by the purchase cost. The CDR magnetic drive pumps, compared above all with mechanical seal pumps, are in fact easy to disassemble and reassemble and if used at the right working point, they reach a useful life of about 10/15 years (hundreds of CDR pumps installed arrive safely even 25/30 years of service).Contact us if you are unsure about the sizing of the centrifugal pump for your application. Our sales office, thanks to its experience, is able to support you in the right choice of the ideal pump by treating the various aspects listed above and going into detail of the individual application.